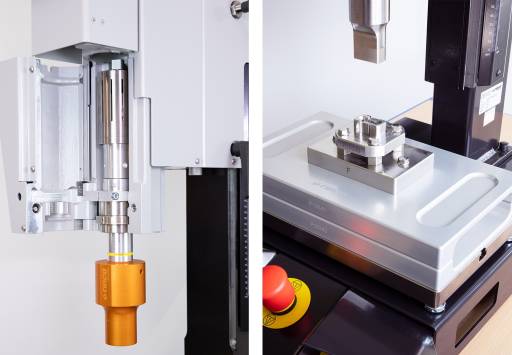

Ultrasonic welding machine Electrical Motion2-35

The Electrical Motion2-35 is ideal for welding, cutting, and punching small to medium-sized thermoplastics, non-wovens and textiles.

The Electrical Motion2-35 ultrasonic welding machine is the perfect partner for demanding and complex ultrasonic welding applications. Thanks to its fully electric drive, the machine impresses with maximum precision and an exceptional level of flexibility. Welding force, speed, and amplitude can be adjusted precisely and independently of each other, as can trigger and slow-down points. This allows you to achieve consistently excellent welding results, even under the most demanding conditions.

A comprehensive audit trail, in which every single event and change are logged, ensures maximum process reliability. This is supplemented by the precise recording of all relevant welding parameters, which can be clearly assigned to workpiece ID, creating the ideal basis for complete traceability.

Multi-level user management rounds out the system, enabling targeted access control based on individual roles and permissions. The Electrical Motion2-35 sets new standards in ultrasonic welding technology – it is powerful, safe, and forward-looking.

Models of the Electrical Motion2 series

Maximum control. Complete connectivity.

Fully controllable melting process

The melting process is divided into ten precisely defined steps, with specific parameters that can be customised in each step. This sophisticated control system allows for precise process control and makes a significant contribution to consistently high welding quality.

Remote access service

Remote maintenance can be set up for quick and efficient fault diagnosis. This allows our after-sales service to provide targeted support, regardless of the machine location.

Data export

The weld data can be exported as a datastring via RS232, Ethernet/a company network or an external storage medium and reliably logged. Optionally, the data can also be read out via PROFINET, which supports seamless integration into higher-level systems.

Process monitoring, traceability and user management

Audit trail

The non-deletable audit trail automatically records and documents all relevant system events as well as changes to machine parameters, user rights and process data. Every action is logged with a time stamp, user ID and detailed description. This ensures dependable traceability and process reliability.

Welding process monitoring

The ultrasonic welding machine is equipped with a system for monitoring the welding process. All relevant process parameters (e.g., welding time, energy, force curve, amplitude, travel) are recorded and examined in real time. If required, the weld data can be clearly assigned to the serial number of the respective component and exported for quality assurance purposes.

Menu-based assignment of user rights

You can assign user authorisations using a menu-based system: Users are granted targeted access to individual menu items, allowing access to specific functions or areas of the user interface to be controlled individually, which increases process reliability.

e-Drive – up to 78% energy cost savings

Thanks to its powerful electric drive, the Electrical Motion2-35 ultrasonic welding machine impresses with maximum precision and energy efficiency. Compared to a pneumatic welding machine, energy consumption can be reduced by up to 78% – and with improved welding quality. This not only significantly reduces operating costs, but also makes a valuable contribution to sustainability in production processes.

13.3" TFT colour touch display

The swivelling, ergonomically designed colour touch display greatly simplifies parameter entry and machine operation. In operating mode, it also displays the name of the currently active parameter data set as well as information on the number of parts already welded as well as rejected parts, production time, the associated serial number and a graphic of the last weld with information on travel, force, and power.

Electrical Motion2 video

In this video, we present the most important features of the Electrical Motion2 ultrasonic welding machine.

Benefits of the Electrical Motion2-35 ultrasonic welding machine

Calibration

The force and amplitude can be calibrated. This makes the welding results reproducible and upholds the quality of your products.

Suitable for cleanrooms

The Electrical Motion2-35 series is suitable for cleanrooms and certified to ISO 14644-1 ISO class 6. As such, it meets the high requirements placed on devices used in the medical sector.

Performance Level – PL e

Our machines deliver optimum safety for operators and maintenance personnel.

Start position can be selected at will

The position of the actuator can be selected at will, reducing the cycle time.

Maximum reproducibility

The database for the ultrasonic welding machines can store as many parameter data sets as required. Weld data can also be saved on the internal hard drive, the company’s own network or on an external storage medium, or be read out via PROFINET.

Adjustable amplitude

You can change the value for the internal or external amplitude to between 40 and 100% in 1% increments so as to achieve the best possible welding result.

8 welding modes to choose from

Thanks to the multitude of welding modes, you can find the right setting for every application, meaning that perfect welding is guaranteed. The following welding modes can be selected on the Electrical Motion2-35:

- Welding time

- Welding energy

- Welding time AND/OR welding energy

- Welding travel (absolute or differential)

- Contact cut-off

- Multi melt monitoring

Multi melt monitoring mode

This mode precisely controls the speed of the melting process.

Force and speed profile

The melting process can be split into 10 steps, meaning that it can be controlled precisely. Various parameters can also be adjusted at each step. These features ultimately lead to an optimum welding result.

Afterpulse

An afterpulse can be activated to prevent lightweight workpieces from potentially getting stuck on the horn.

Trigger (ultrasonic trigger point)

The welding operation can be initiated using a trigger. You can choose from the following triggers:

- Time

- Travel

- Force

- Off

- External signal

- Travel absolute and force

Options

Quick-change system for tools

Thanks to the quick-change system, tools can be replaced within just a few minutes. This minimises the risk of errors. The removable carriers are indexed. Quick-change systems are available for oscillator systems and anvils.

Bar code reader

A bar code reader can be used to scan a welded component's bar code/QR code and assign it to a specific welding result. Scanners are available as hand units or permanently mounted units.

Two-hand start pushbuttons

The Electrical Motion2-35 is also available with pushbuttons instead of safeballs as an option.

Technical specifications

| Ultrasonic welding machine Electrical Motion2-35 | Ultrasonic welding machine Electrical Motion2-20 | |

|---|---|---|

|  | |

| Operating frequency | 35 kHz | 20 kHz |

| Maximum force | 750 N | 3000 N |

| Drive | Electric, 230 VAC | Electric, 230 VAC |

| Maximum stroke | 100 mm | 100 mm |

| Weight | 53 kg without generator | 135 kg without generator |

| Height adjustment | 0 - 180 mm | 0 - 280 mm |

| Compatible generators |

Downloads

Download here our product brochures.

Fields of application

Contact

Think this device might be right for you, but you still have some questions? Please feel free to contact us for more information.