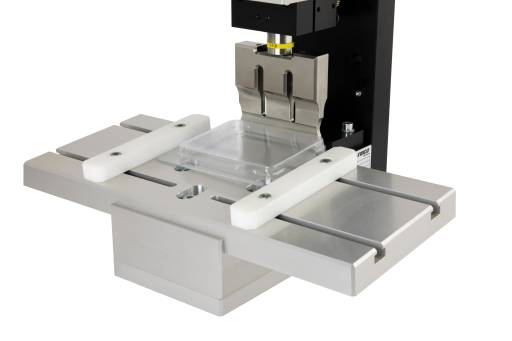

Ultrasonic blister welding machine ABW35

Our ABW35 ultrasonic blister welding machine makes it so much easier to weld blister and film packaging, as well as coated and laminated packaging. This compact welding device needs neither a foot start nor a two-hand start. Once the packaging is in the correct position, the ultrasonic welding process is started automatically with the integrated and adjustable microswitch. This achieves very rapid cycle times while guaranteeing extremely user-friendly operation.

There is a wide range of standard tools available. If you have specific requirements, we can produce custom tools for you.

Flexible: Weld plastic packaging or cut textiles

The ABW35 ultrasonic blister welding machine can be used to weld or seal plastic packaging such as blister and film packaging, as well as coated and laminated cardboard packaging. But that’s not all – this packaging machine is also suitable for cutting, welding and sealing textiles.

Stroke movement

The pressure and speed of the stroke movement are adjustable, allowing the welding cycle and welding result to be optimised. It is also possible to regulate the force buildup over time after touch down of the horn on the blister or other packaging. For occupational health and safety, a stroke limiter with adjustable safety distance is fitted.

Trigger (ultrasonic trigger point)

The welding operation can be initiated using a trigger. You can choose from the following triggers:

- On (for external signal)

- Off

- Time

5 welding modes to choose from

Thanks to the welding modes, you can find the right setting for every application, guaranteeing perfect welding. Welding modes define the conditions under which the welding process ends. The following welding modes can be selected on the ABW35:

- Welding time

- Welding energy

- Welding time AND welding energy

- Welding time OR welding energy

- Contact cut-off

Flexible working area

The ABW35 ultrasonic blister welding machine can be set up on a workbench or mounted on a wall. Thanks to the modular construction of our components, a manual workstation can be developed into an automation line or integrated into a special purpose machine at any time.

ABW35 ultrasonic blister welding machine video

Our video demonstrates how quickly and easily the ABW35 seals blister packaging with ultrasonics.

Advantages of the ABW35 ultrasonic blister welding machine

Quick to set up

The ABW35 ultrasonic blister welding machine is ready for operation in an instant.

Visual indicator for the user

Status LEDs on the generator show the operator whether the generator is ready for operation, whether the ultrasonics are active or whether an error has occurred.

Soft start and soft stop function

This mode gently augments and attenuates the oscillations of complex horns.

Increase process reliability

All ultrasonic blister welding machines in the ABW series feature an integrated part counter and rejected parts counter.

Set limits

You can set a wide range of limits that issue a warning or stop the machine.

User administration

Multi-level user administration is available to help you safeguard quality.

Reliable and time-saving

RINCO products are very reliable in operation and offer a long service life. They are also virtually maintenance-free.

How does ultrasonic sealing work?

On our knowledge pages, we explain how ultrasonics can be used to weld or seal packaging. Discover the advantages of ultrasonic welding and cutting.

Find out more about ultrasonics

Options

Feeder rail

The feeder rail makes it easy to position the blister in exactly the right place.

Footswitch

The welding cycle of the ABW35 can also be triggered with a footswitch if packs have very narrow edges.

Standard tools

We supply various standard tools for your ABW35 ultrasonic blister welding machine, allowing you to seal blister and film packaging and weld textiles. Alternatively, we can produce custom tools for you.

Technical specifications

| ABW35 | |

|---|---|

| |

| Operating frequency | 35 kHz |

| Maximum force | 745 N |

| Drive | Pneumatic, double acting cylinder |

| Maximum stroke | 6 mm |

| Weight | 11,2 kg |

| Height adjustment | 0 - 28 mm |

| Compatible generators |

Downloads

Download here our product brochures.

Fields of application

Contact

Think this device might be right for you, but you still have some questions? Please feel free to contact us for more information.