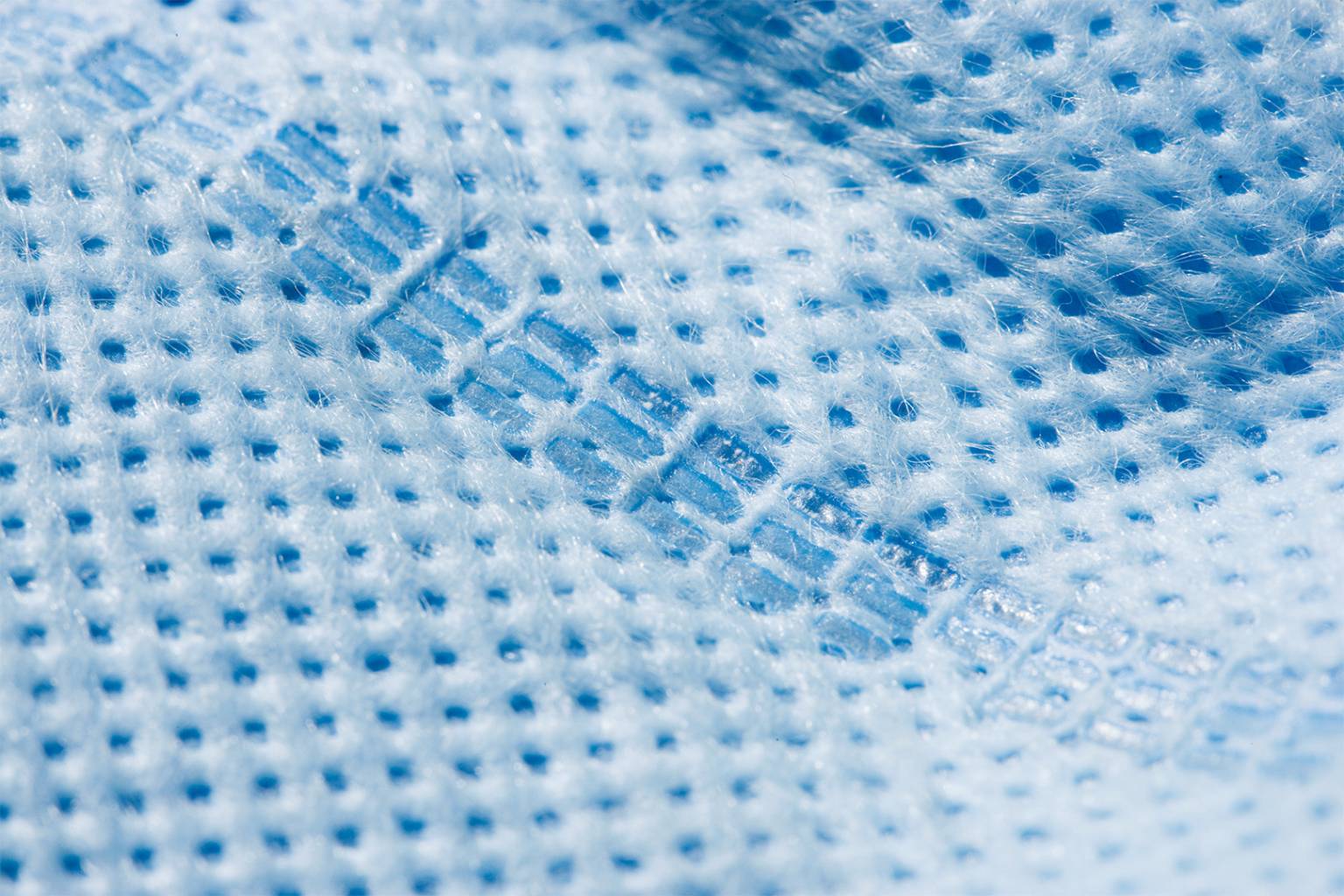

Non-woven & Textile

Ultrasonic technology can be used for a wide range of processes. Whether it is used for cutting with edge sealing, welding, cutting and sealing, roller seam welding, embossing or punching, there are virtually no limits when it comes to seam designs. Ultrasonic textile welding can even join together different material types. With ultrasonic cutting, the edges of synthetic or mixed fabrics are cut and sealed cleanly and with precision in a single process. Now, there's no need to worry about the drawbacks of methods that use hot wire or rotating blades – fraying, unravelling and bubbling along the cut edges are resigned firmly to the past. At RINCO ULTRASONICS, you will find the right device along with the best advice.

Versatile use

Benefits of ultrasonic cutting and ultrasonic welding of synthetic textiles

The highest levels of quality for welding results, well-chosen materials for tools and absolute process control thanks to recording software for validation purposes and quality assurance monitoring. Textile applications are ideal for processing with ultrasonic technology.

Consistent, accurate and reproducible welding results

Made possible by a database of welding parameter sets, an audit trail and very high product quality.

Flexible weld seams and clean cut edges

Ultrasonics induces material compression in the edge area, where the material remains flexible. Furthermore, it seals the cut edges and prevents fraying. There is thus no need to adjust the edges after cutting.

Med ultralyd sparer du ikke kun tid, men også energi og materiale.

Ultrasonics not only saves you time but also uses less energy and fewer materials.

Very short maintenance times

Service work can be completed in next to no time on our low-maintenance machines.

Continuous, contour or flexible cutting

Ultrasonic cutting can be used for a variety of purposes in the field of technical textiles and non-wovens.

High-speed/high-frequency cutting

Ultrasonic cutting is a fast process: depending on the material and your requirements, speeds of up to 120 cuts per minute can be achieved for products like textile labels, or 25 metres per minute in continuous cutting applications.

Cutting and joining in a single step

With ultrasonic technology, you can cut and weld two separate adjoining layers in a single step. The ultrasound gently melts the fabric to permanently join the two components.

Minimum generation of particles and dust

Ultrasonics can be used to cut and seal textiles with certain thermoplastic content in a single operation. Compared with mechanical cutting, this prevents dust generation and fraying.

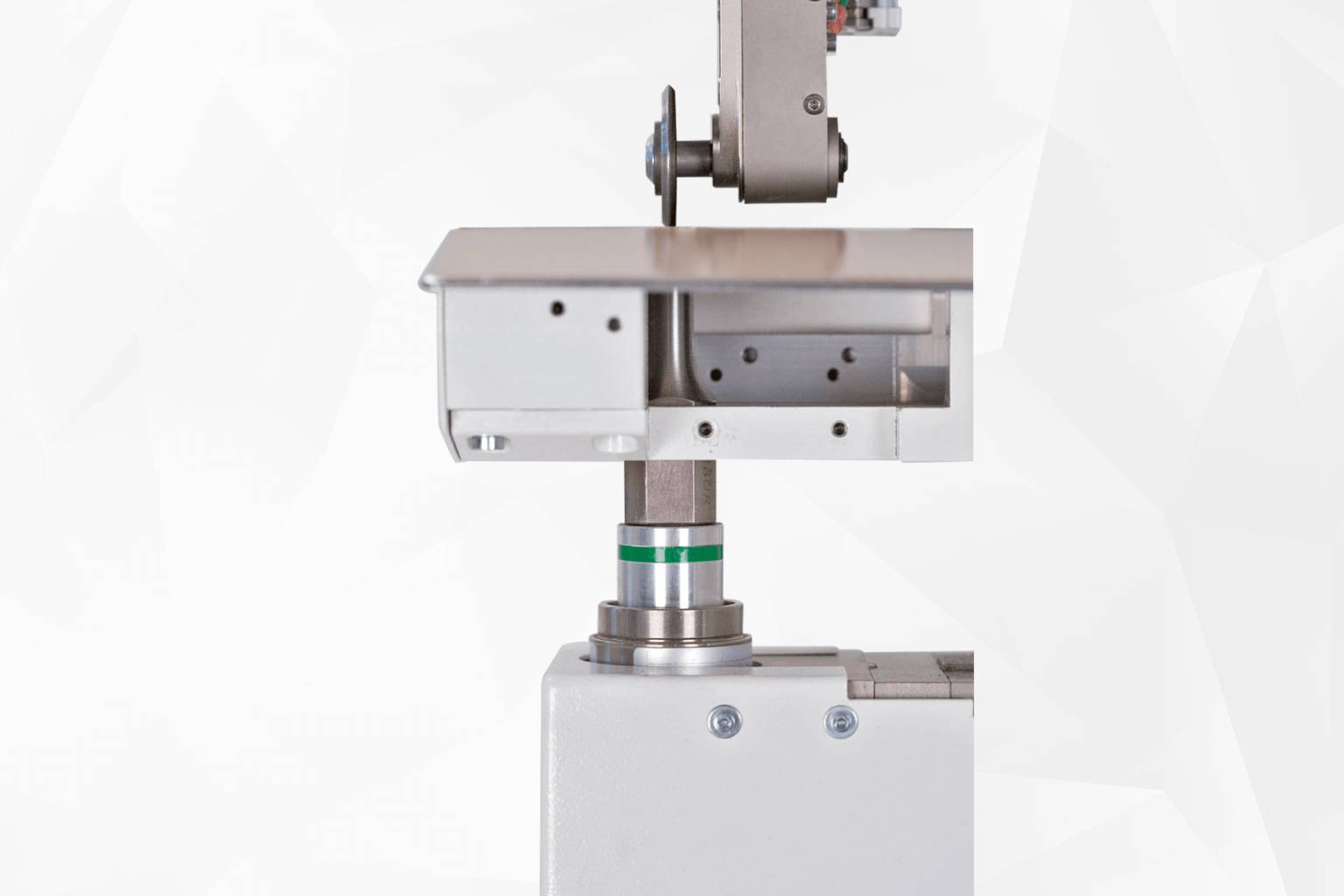

Our tools - well-chosen materials, suitable coatings, low wear and tear

Our tools are custom-developed and calculated and simulated using FEM analysis. They are made from select materials. Their high quality guarantees a long service life. Thanks to our quick-change system, tools can be replaced within just a few minutes, reducing downtimes to a minimum.

Automation & integration

RINCO generators and robot-controlled cutting tools are used for cutting lengths of material, for example, where the material edge is simultaneously cut and sealed. The modularity of this application is also ideal for integrating standard products such as actuators and generators into automation lines or special purpose machines. We can even supply special OEM products like the AGM Pro generator, which can be controlled entirely via a system's own PLC. Multiracks support the operation of multiple generator modules.

Ultrasonic technology

Non-wovens and technical textiles containing thermoplastics can be cut, punched, welded and sealed in an intermittent or continuous operation.

Downloads

Download our application brochure here.

Economical, energy-saving & efficient technology

The right device for every application. We provide you with tailored technology. Contact us and we will be happy to advise you.

I am here for you

Not sure whether ultrasonic technology is right for your application? Then get in touch with me!