Ultrasonic technology

If your business involves sealing packaging, welding plastic moulded parts, punching out components or cutting textiles or food products, then ultrasound could be the perfect addition to your production process. Ultrasonic technology is fast, energy-efficient and economical with materials, guaranteeing speed, precision and efficiency.

Join us on a journey of exploration. We explain how our ultrasonic technology works, how our machines are designed and what you can do with them – all in a way that’s easy to understand. We might just have the solution you need to optimise your production process.

What is ultrasound?

Ultrasound is mechanical oscillation with a frequency between 20 kHz and 10 GHz. This means that it is inaudible to humans, as we can only hear sounds between 16 Hz and 20 kHz.

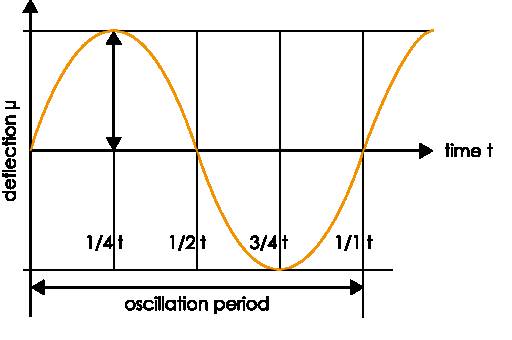

Ultrasound is generated using high-frequency electrical energy, which is then converted to mechanical energy. As a form of mechanical oscillation, the sound travels through the air and other media at a defined speed as a wave of pressure. Frequency is a measure used to express how often the cycles of a periodic process – like the contracting and deforming motions of our ultrasonic tools – recur. One hertz is equivalent to one oscillation per second.

How does the ultrasonic welding and cutting process work?

To weld and cut using ultrasound, we use the energy converted to sound waves to melt the plastic. The frequency varies depending on the application. As RINCO ULTRASONICS covers a full spectrum of frequencies between 20 and 70 kHz, we can provide perfectly tailored ultrasonic solutions for any welding or cutting application.

The ultrasonic process

This video shows exactly how the process works, from start to finish.

How does mains energy get converted into ultrasound?

To convert electrical energy (electricity) into mechanical oscillations (ultrasound), you need a generator and a converter. The generator first converts the 200/230 V mains voltage and 50/60 Hz (socket) energy into a HF voltage with a defined frequency of at least 20 kHz. Depending on the application, the frequency can be anywhere between 20 and 70 kHz.

The downstream converter turns the high-frequency electrical energy into mechanical oscillation. Inside the converter, there are a number of piezo discs, which respond to the electrical energy by alternately contracting and deforming. This movement causes the converter to oscillate. The resulting ultrasound is emitted at an amplitude and frequency set by the generator, which are transmitted by the converter to the downstream booster and the sonotrode.

The sonotrode is the actual welding or cutting tool that makes contact with the workpiece.

Often, the converter, booster and sonotrode are collectively referred to as the oscillation system. These components must be acoustically fine-tuned to work together efficiently.

How can ultrasound be used to weld or cut plastics, textiles or food products?

In ultrasonic joining or ultrasonic welding, the mechanical oscillations generated in the converter are transferred to the workpiece via the sonotrode. These oscillations generate frictional heat, which causes the plastic molecules to oscillate. In response, the plastic melts and plastifies. The plastic can then be reshaped by applying joining pressure. This process can be used not only for welding, but also for bending, riveting, fusion forming and inserting, as the basic principle of ultrasonic welding applies to all join variants.

In ultrasonic separation or ultrasonic cutting, the mechanical oscillations are transferred to the material via a blade. Using minimal pressure and the surface friction generated when the blade contacts the material, this technology can be used to cut plastic, textiles, rubber and various food products. Frictional heat also plays a key role in ultrasonic cutting. It makes the cutting process easier, enabling you to cut with minimal pressure so that even softer food products retain their shape. The technique also produces exceptionally clean cuts. On textiles, the application of heat not only ensures a clean cut, but also immediately seals the cut edges to prevent fraying.

What does a typical ultrasonic (welding) process look like?

To recognise ultrasonic welding, you have to look very closely. Here, we explain the process using the ultrasonic welding cycle as an example. An ultrasonic welding cycle is very brief. It is usually comprised of six steps, which all happen in quick succession in a single stroke movement.

In step 1, the actuator moves from the start position to the brake position with the oscillation system. The highly dynamic motion of this first step slows down at step 2, when the sonotrode is gently placed on the workpiece. In step 3, the pressure is reduced to a pre-defined value (the trigger point) before the ultrasound is transferred to the workpiece in step 4. This is when the actual welding process – which often only lasts for a fraction of a second – takes place. The machine continues to apply pressure for the cooling phase (step 5), before the actuator moves back to its original position in step 6.

These six positions can be precisely adjusted to suit your application and material, enabling you to safely join any plastic component. This process applies to both welding and reshaping. With punching, the pressurised cooling phase is omitted. The process for cutting is explained in more detail under Ultrasonic cutting.

What requirements can I meet with ultrasonic technology?

Ultrasonic technology is energy-efficient, fast and clean. It is ideal if you’re looking to achieve short process times combined with high levels of process reliability. Ultrasonic technology should also be considered if you need high join quality and outstanding aesthetic results, high-strength joins and exact reproducibility. It is also ideal for applications where you need or want to avoid additional components, additives or adhesives.

Ultrasonic components are easily integrated into existing systems.

Explore the relevant sub-menus to learn more about how each ultrasonic process meets your requirements.

What materials can I join or cut using ultrasound?

Ultrasonic technology is a joining process that combines speed with energy efficiency and economic use of materials. It’s also highly versatile. Ultrasound is a great option if you work with thermoplastics. For example, it’s easy to join thermoplastic moulded parts using ultrasonic technology. This technique is widespread in the automotive, high-tech and medical industries. Ultrasound can be used to create reliable seals and welded joins on films. Technical textiles and non-wovens with a thermoplastic component can also be efficiently joined or cut using ultrasonic technology.

In the food industry in particular, ultrasound can be used not only to seal packaging, but also for portioning and cutting. Confectionery, baked goods, cheese, vegetables and wraps can all be cut into precise, equal portions and placed in their packaging in attractive shapes and with clean-cut edges.

What materials can I join or cut?

Ultrasonic joining is suitable for use on all thermoplastics. Thermoplastics are classed as either semi-crystalline – such as POM, CA, LCP, PEEK, PA, PBT, PE, PPS, PP and PTFE – or amorphous. The amorphous category includes ABS, MABS, PMMA, PC, PET, PS and PVC. Generally, the best results are achieved when welding two components made from the same material, but you can also weld compatible pairings of different materials. Chlick here to learn more.

The applications of ultrasonic technology extend far beyond joining plastics; ultrasound can also be used to cut materials. In addition to plastic, rubber, non-wovens and technical textiles, ultrasonic cutting can be deployed to cut and portion many food products – with the advantage of clean-cut edges and no blades to keep clean.

Layout of a typical ultrasonic welding machine

Ultrasonic welding machines are comprised of a generator with a control system, a press column, an actuator and the oscillation system. The oscillation system is made up of the converter, the booster and the sonotrode. The machine is also equipped with a workpiece mount, a base plate and an activation unit for individual workstations.

Generator (1)

The ultrasonic generator has multiple roles to play. It converts the alternating current from the socket and uses it to generate the required high voltage at a frequency of 20 to 70 kHz. It also controls the amplitude of the voltage and supplies electrical energy to the converter. Rinco Ultrasonics offers generators with various power levels. The device control system is usually integrated into the same housing. Ultrasonic welding devices are usually operated via a local or external touch display. Generators are available complete with a housing or as a stand-alone ultrasonic generator module supplied without a housing.

Press column (2)

The actuator is mounted on the press column; this component is responsible for the overall stability of the machine.

Actuator (3)

The actuator is responsible for the stroke movement. The drive for this moving component may be pneumatic or electrical. The oscillation system is attached to the actuator.

Oscillation system (4)

The oscillation system attached to the actuator is the beating heart of the ultrasonic machine, as this is where the ultrasonic oscillation is generated.

It is comprised of a converter, a booster and the sonotrode.

Converter (5)

The ultrasonic converter – which is also referred to as a transducer – converts electrical energy into mechanical oscillations. These oscillations are created when a high-frequency voltage is introduced to the piezo crystals in the piezo discs.

Booster (6)

The physical design of the booster enables it to amplify the generated ultrasonic oscillations by increasing their amplitude.

The entire oscillation system is attached to the machine or the robotic arm via the booster.

Sonotrode (7)

The sonotrode is the actual welding or cutting tool. It transmits the ultrasonic oscillations to the workpiece, which melts when the ultrasound is applied and hardens as it cools.

The sonotrode is attached to the booster and is made of aluminium, titanium or steel. Each sonotrode is individually designed and manufactured to suit the customer’s workpiece. To achieve a perfect weld, the sonotrode must be manufactured to the highest degree of precision and customised for the exact frequency of the application.

Anvil (8)

To prevent the workpiece from sliding out of place and to provide optimum support during the ultrasonic welding process, the workpiece is placed in a fixture. This anvil is often also referred to as a mount or workpiece holder.

Base plate (9)

The anvil is attached to the base plate. The height of the base plate can be adjusted for perfect alignment with the sonotrode to ensure a high-precision welding result.

Activation unit (10)

The activation unit is used to start the actual ultrasonic welding process. To ensure the safety of the machine operator, the ultrasonic welding process can only be started with two hands. The emergency stop switch, which is attached to the activation unit, provides an additional layer of safety.

What are the practical benefits of ultrasonic welding and ultrasonic cutting?

Ultrasonic welding and ultrasonic cutting are versatile techniques that are both economical and environmentally friendly.

Strong joins

Ultrasonic welding enables you to achieve high-strength joins.

The ultrasonic energy causes thermoplastics to bond at molecular level to create a join with high mechanical strength. The resulting join is resistant to deformation and/or hermetically sealed.

Efficient, economical, short cycle times

The ultrasonic process is efficient both in terms of material usage and time. It’s also economical; cycle times are very short, and joins or cuts can be created rapidly at any time with ultrasonic technology. The welding process itself usually only takes a fraction of a second. This means that ultrasonic machines benefit from low energy consumption.

High-precision technology

Welding and cutting using ultrasound is an exact technique. The welding parameters for ultrasonic welding can be configured with a high degree of precision. Electrically powered ultrasonic welding devices achieve particularly precise welding results.

Ultrasonic cutting, too, is a high-precision technology, guaranteeing exact cuts and exceptionally clean edges.

Attractive welding results

The high precision of ultrasonic welding means that you can achieve exceptionally attractive results that will fulfil any aesthetic requirements you may have – whether that’s a visually appealing seam and rivet join or a mark-free surface.

Food product cutting is another area where ultrasonic technology can be used to produce aesthetically pleasing results. Ultrasound enables you to cut food products without deformation, even if they have layers with different textures and consistencies, like a vanilla slice.

Economical and quick to set up

Short process times reduce costs. Ultrasonic welding machines and ultrasonic cutting devices are ready for use immediately, with no warm-up time – giving the technology a major advantage over thermal joining methods like hot caulking or hot plate welding.

Furthermore, because the workpiece only heats up very slightly during the welding process, the weld seam hardens in under a second once the welding cycle is complete.

A gentle process for sensitive products

Ultrasonic technology is ideal for use with temperature-sensitive products.

When welding plastics – or cutting any material – with ultrasound, gentle heat is applied only to the weld seam or the cut surface itself, which makes the technology suitable for a wide range of applications.

Ultrasonic sealing is highly recommended for packaging heat-sensitive products like cosmetics, medications or food.

Clean, environmentally friendly and sustainable welding and cutting

Ultrasonic welding and ultrasonic cutting are among the most sustainable and environmentally joining and cutting techniques.

When used to join two thermoplastics, ultrasonic welding requires no additional materials like adhesives or screws. As the process uses no additives or additional components, ultrasonic welding makes it easy to separate plastics for recycling and reduces resource consumption in the long term.

As heat is only generated in the exact locations where it is needed, energy consumption is minimised. The plastic components themselves require no pre-treatment, which also helps to protect the environment. And with no additives required, the process is clean and simple.

Ultrasound: The foundation of a versatile technology

Ultrasonic technology can be used in many different processes: from welding, cutting and cutting/sealing to punching, sealing, fusion forming, riveting, bending and inserting.

What kinds of processes can use ultrasound?

Ultrasonic technology is suitable for use in a wide range of manufacturing processes and techniques involving many different materials, textiles or food products.

At RINCO ULTRASONICS, our ultrasonic welding devices are our most popular solution. Thanks to the short cycle times, plastic welding with ultrasound is primarily used to produce and process components for the automotive sector.

Ultrasonic welding

Ultrasonic welding is an efficient and sustainable process for joining two thermoplastic materials. Films, injection-moulded parts and synthetic textiles can be welded in milliseconds with minimal energy consumption – resulting in clean and attractive weld seams and no visible marks on completion of the welding process.

Ultrasonic cutting

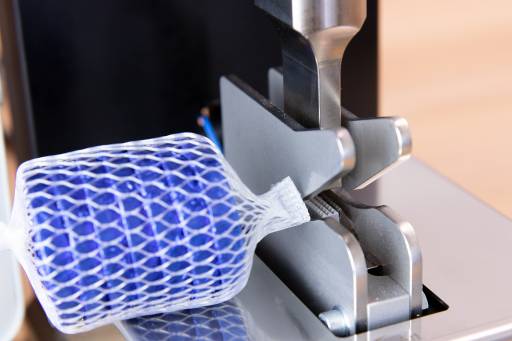

The ultrasonic devices manufactured by RINCO ULTRASONICS cut synthetic textiles, rubber/plastic and food products.

The high-precision ultrasonic technology allows you to cut food products without leaving residue on the tool and without deformation.

In textile processing, ultrasound produces clean and sealed cut edges in a single step. Ultrasound even makes light work of cutting through rubber.

Ultrasonic punching

Ultrasound can be used to punch thermoplastic moulded parts and technical textiles. With thermoplastic materials, beautiful, rounded edges are created automatically, without any white breaks. With synthetic textiles, cut edges are cleanly sealed during the punching process.

Ultrasonic sealing

The ultrasonic sealing process is highly economical with materials. Thanks to the short cycle times, this technique is very popular in the packaging sector, and is also ideal for modern, high-output production lines. Even if contamination is present – if water makes its way into a narrow seam, for example – the process guarantees a strong join.

Ultrasonic fusion forming, ultrasonic riveting, ultrasonic bending

In ultrasonic fusion forming, thermoplastic materials are riveted or bended to components made of the same or other materials. The process produces rigid, zero-play joins that are guaranteed to last.

Ultrasonic inserting

Ultrasonic inserting is a process step in which metal components are pressed into moulded parts using ultrasound. The process is fast, requires little energy and guarantees high-precision results. The metal does not need to be pre-heated, which means you can get started immediately.

Frequently asked questions about ultrasonic technology

How is ultrasound generated?

High-frequency electrical energy is introduced to piezo crystals to make them contract and deform. The ultrasonic generator controls the speed and amplitude of these movements. Further information can be found under “How does mains energy get converted into ultrasound?”

How can ultrasound be used to join plastics?

The mechanical oscillations of the ultrasound and the resulting frictional heat plastify plastic materials at a molecular level. When the ultrasound source is removed, the molecules join up again and the plastic hardens to create a permanent join. See also “How can ultrasound be used to weld or cut plastics, textiles or food products?”

Can ultrasound be used to hermetically join plastics?

Yes. Hermetically sealed weld seams are of particular importance in the food packaging and medical technology sectors. Ultrasonic welding or ultrasonic sealing can be used to achieve this type of seal.

How long does the ultrasonic welding process take?

The process is very quick; sometimes, it can be completed in less time than it takes to blink. However, it’s difficult to provide a general answer to this question, as the welding duration depends on the application. Generally, the welding stage takes a few milliseconds. The entire joining process, including the cooling phase, usually only takes a few seconds. See also “What does a typical ultrasonic (welding) process look like?”

What ultrasonic frequency is used to join or cut materials?

Ultrasonic welding and ultrasonic cutting uses frequencies between 20 and 70 kHz.

If I opt to use ultrasound, why do I need to decide on a frequency of 20, 35 or 70 kHz?

The right frequency for any given application depends on a number of different parameters. Alongside the material type and the size of the product, the distance from the coupling surface (the surface you are welding) and the thickness of the material also play a part. The more material the ultrasound needs to penetrate en route to the coupling surface, the more energy is lost through attenuation in the material.

Another reason why it is important to decide on a frequency is that the sonotrode needs to be adjusted to this frequency. Large tools, for example, can only be operated at lower frequencies of 20 kHz.

Can existing ultrasonic tools, or sonotrodes, be adjusted?

No, this is not usually possible. Any change to a sonotrode will affect its natural frequency, which can result in resonance. In turn, this will usually cause errors in the welding process. Sometimes, the sonotrode may even get damaged and break. For new applications, the best approach is to use a new sonotrode and recalibrate the frequencies.

The workpiece mount, on the other hand, can be adjusted to suit new product geometries or products at any time, as it is not affected by the welding frequency and has no impact on resonance.Is ultrasound dangerous?

No, ultrasound is not dangerous. However, the design of some parts can amplify the acoustics, which you may experience as an unpleasant squeaking sound. For this reason, we recommend wearing hearing protection during the welding process.

What machines are available for ultrasonic welding and ultrasonic cutting?

We supply individual workstation devices in the form of bench-top workstations or hand-held devices. However, we also offer ultrasonic components that OEMs can install in special machines and automation lines. Browse our entire range here.

Do machines and devices for welding and cutting need to be heated up or prepared before use?

No, there is no need for pre-heating or similar preparatory steps. Ultrasound machines and devices are ready for use immediately.

Can ultrasound be used to achieve reproducible welding and cutting results?

Yes, ultrasonic technology provides consistent and reproducible welding results. Our machines and devices are built to the highest levels of quality and guarantee clean welds and cuts.

What is amplitude?

Amplitude is the maximum deflection of a harmonious oscillation from the position of the mathematical average.

Who discovered the “piezo effect”?

Pierre Curie and his brother Jacques discovered the piezo effect in 1880.

How fast does ultrasound travel in aluminium, steel or titanium?

Around 6000 metres per second.

Do ultrasonic oscillations travel in a longitudinal or transversal direction?

Ultrasound generally oscillates in a spherical shape, but the design of our products means that the waves travel in a longitudinal direction.