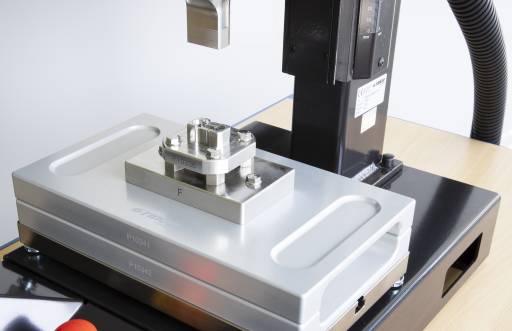

Ultrasonic welding machine Easy 3000

The Easy 3000 ultrasonic welding machine is proportionally pneumatically driven and is suitable for welding, cutting and punching thermoplastics, non-wovens and synthetic textiles. But like all of our machines, it is also suitable for riveting, embossing, bending, embedding, die-sinking and sealing plastics and fabrics. It is suitable for processing medium to large components.

This inexpensive welding machine can achieve clean and repeatable welding results. The advantages of this ultrasonic welding machine are the repeatable welding force and the fact that it offers good value for money. If you are planning to automate your production process at a later date, the Easy 3000 can be integrated into a special purpose machine or production line without any problems.

Easy series models

Trigger (ultrasonic trigger point)

The trigger starts the ultrasonic welding process. You can choose from the following triggers:

- On

- Off

- Time

- Start

6 welding modes to choose from

Welding modes define the conditions under which the welding process stops. As there is a large selection available, it is possible to select the ideal welding mode for any application so that the optimal weld seam or cut is achieved. The following welding modes can be selected on the Easy 3000 ultrasonic welding machine:

- Welding time

- Welding energy

- Welding time and welding energy

- Welding time or welding energy

- Contact cut-off

- Continuous welding or cutting

Status LEDs – small devices, big impact

Status LEDs on the generator show the operator whether the generator is ready for operation, whether the ultrasonics are active or whether an error has occurred. This makes a more efficient working process possible.

Increase process reliability

Just like all ultrasonic welding machines from RINCO ULTRASONICS, the Easy 3000 features an integrated part counter and rejected parts counter.

Easy 3000 ultrasonic welding machine video

Our video demonstrates how easy it is to set up and operate the Easy 3000 ultrasonic welding machine.

Advantages of the Easy 3000 ultrasonic welding machine

Quick and easy to set up

The Easy 3000 ultrasonic welding machine is set up and ready for operation in an instant.

User administration

Multi-level user administration is available to help you safeguard quality.

Afterpulse

To prevent lightweight workpieces from potentially getting stuck on the horn, an afterpulse can be activated.

Flexibility

Thanks to the modular construction of our components, a manual workstation can be developed into an automation line or integrated into a special purpose machine at any time. The Easy can also be integrated into RINCO sound enclosures and RINCO workstations.

High level of process reliability

The Easy 3000 is reliable when it comes to reproducing the welding force. The multi-level user administration provides additional safety together with the different limit values, which trigger a warning or stop the machine when they are reached or exceeded.

Adjustable amplitude

You can change the value for the internal or external amplitude to between 15 and 100% in 1% increments so as to achieve the best possible welding or cutting result.

Optimal safety equipment

The two-hand start device is equipped with an EMERGENCY STOP button. What’s more, all RINCO ultrasonic welding machines are CE-compliant.

Reliable and time-saving

RINCO products are very reliable in operation and offer a long service life. They are also virtually maintenance-free.

Options

Quick-change system for tools

The quick-change system allows you to change welding and cutting tools in just a few minutes. This minimises the risk of errors. The removable carriers are indexed to minimise the risk of confusion.

Protection against marks

The ultrasonic process is generally a gentle process. However, if the surface requires special protection against marks, we offer an optional film actuator. The film is tensioned between the horn and the workpiece being welded. The surface is protected and the welding result is perfect.

Service tool

For maintenance of the Easy 3000 ultrasonic welding machine, a tool case is available that contains all of the tools needed to easily complete the few necessary maintenance tasks or change any tools.

Technical specifications

Downloads

Download here our product brochures.

Fields of application

Contact

Think this device might be right for you, but you still have some questions? Please feel free to contact us for more information.