AGM2 ultrasonic welding generator

Generators from the AGM2 series are designed for installation in automated lines and special purpose machines to control ultrasonic actuators and components. Thanks to their slim design, they can be incorporated into small spaces in electrical cabinets.

Thanks to fieldbus interfaces and the ProConnect web application, ultrasonic generators are the ideal addition to your Industry 4.0 concept.

Communication and integration

The generators are controlled via the system’s own PLC. Certified interchangeable modules for fieldbus interfaces make it possible to integrate them easily into existing systems. Communication modules for PROFIBUS, PROFINET, DeviceNet, EtherNet/IP, EtherCAT and CANopen fieldbuses are available. It is also possible to integrate the ultrasonic generators via RS485 plus digital and analogue inputs and outputs.

Operating concept

In addition to the PLC, you can use our intuitive and user-friendly ProConnect web application to enter and change parameters or export and analyse data with ease. These two options can also be used for real-time status monitoring.

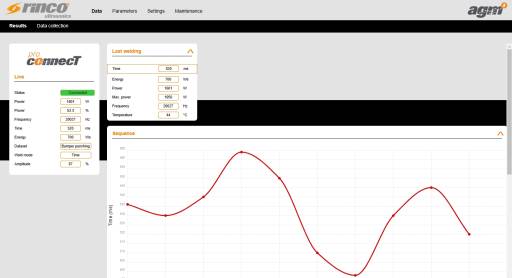

PROCONNECT WEB APPLICATION

Online analysis and parameterisation on your terminal

Editing parameters and data sets has never been easier. Analyse processes at any time and in any place. The user-friendly ProConnect web application offers these and even more possibilities.

Try it for yourself – you'll be convinced!

The AGM2 is typically used in the following applications:

- Ultrasonic welding, cutting, punching, riveting and crimping of plastics

- Ultrasonic embedding and counterboring of metal parts

- Ultrasonic sealing of packaging

- Ultrasonic welding, cutting or cutting and sealing of technical textiles and non-woven materials

- Ultrasonic cutting of foodstuffs, textiles, films and rubber

AGM2 – ultrasonic welding generator for OEM and special purpose machines

In this video, we explain the features and advantages of the AGM2.

Advantages of the AGM2 ultrasonic welding generator

Communication interfaces

The AGM2 generators can be integrated easily into the existing system using fieldbus interfaces. Certified* communication protocols available for use: PROFINET*, PROFIBUS, DeviceNet*, EtherNet/IP*, EtherCAT* and CANopen*. It is also possible to establish communication with the ultrasonic generators via RS485 plus digital and analogue inputs and outputs.

User management

The multi-level user administration provides added security. This means that operators only have read access rights, while technicians have both read and write access rights. Technicians are able to change the password at any time.

ProConnect web application

The ProConnect web application allows you to operate the AGM2 easily from a PC or a mobile device. This allows you to keep a constant eye on the device status and the latest parameters and settings. During the welding process, the current values are displayed as a diagram and are therefore immediately ready to be analysed. You can also use the ProConnect web application to perform remote maintenance.

Maximum repeatability

Generate and store eight parameter data sets to increase the repeatability of your processes.

Data transfer, data recording and traceability

You can use the USB port to back up, restore or copy parameter data sets from device to device. To ensure traceability, you can also save the current welding data – either continuously or at the end of each welding process. Each data set has a timestamp.

Bootloader

Software updates can be performed easily via the USB port.

6 welding mode options

Thanks to the welding modes, you can find the right setting for every application, guaranteeing perfect welding. The following welding modes are available for selection from the AGM2 series:

- Welding time

- Welding energy

- Welding time AND/OR welding energy

- Contact cut-off

- Continuous

Optimised cooling management

The slimline design of the AGM2 series generators allows them to fit neatly into electrical cabinets. They also feature a fan that keeps operating temperatures low. The filter mats can be replaced.

Amplitude control

The amplitude can be adjusted in 1% increments between 15 and 100% for an even better welding result.

Quality control

The ultrasonic generators can be used to set various limits that issue a warning or error message if they are breached.

Softstart and softstop function

The softstart and softstop function delivers protection by ensuring that the sonotrode augments and attenuates gently.

Digital error coding

Errors are split into Generator, Oscillator system and Limits groups to facilitate troubleshooting.

Technical specifications

| AGM2 | AGM Pro | |

|---|---|---|

|  | |

| Operating frequency | 20 kHz, 30 kHz, 35 kHz, 40 kHz or 70 kHz | 20 kHz, 30 kHz, 35 kHz, 40 kHz or 70 kHz |

| Power output | 100 W, 400 W, 500 W, 750 W, 800 W, 900 W, 1000 W, 1500 W, 2000 W or 3000 W | 100 W, 400 W, 500 W, 750 W, 800 W, 900 W, 1000 W, 1500 W, 2000 W or 3000 W |

| Operating modes |

|

|

| Communication and interfaces |

*As interchangeable module |

*As interchangeable module |

| Power supplies |

|

|

| Amplitude | Adjustable 15 - 100 %, changeable in 1 % increments | Adjustable 15 - 100 %, changeable in 1 % increments |

| Weight | 3 kg | 4 kg |

Downloads

Download here our product brochures.

Fields of application

Contact

Think this device might be right for you, but you still have some questions? Please feel free to contact us for more information.