Packaging

The highest levels of quality for welding results, wellchosen materials for tools and absolute process control thanks to recording software for validation purposes and quality assurance monitoring. RINCO offers you everything you need for a production process at the highest level. Our components can be integrated into production lines quickly and with ease. Discover the versatile application of sonic sealing, ideal for the precise ultrasonic film sealing, ultrasonic package sealing and for creating hermetic seals.

The highest levels of quality and precision: with versatile ultrasonic sealing technology to create a quality product

Benefits of ultrasonics in the packaging industry

Gentle welding process

The product is not heated up.

No problems with product build-up

Welding results are of perfect quality in spite of possible product build-up around the seam.

Material savings

Narrow sealed seams enable significant material savings.

Optimization of the process

High process speeds and short process cycles can be achieved with ultrasonics.

High flexibility

Thanks to the modular construction of our components, a manual workstation can be developed into an automation line or integrated into a special purpose machine at any time.

Economical, energy-saving and efficient

Ultrasonics not only saves you time but also uses less energy and fewer materials.

Consistent, accurate and reproducible welding results

Made possible by a database of welding parameter sets, an audit trail and very high product quality.

Very short maintenance times

Service work can be completed in next to no time on our low-maintenance machines.

Video – Ultrasonic welding of a net of chocolate coins

This video demonstrates how quickly and reliably the ultrasonic welding of packaging nets works.

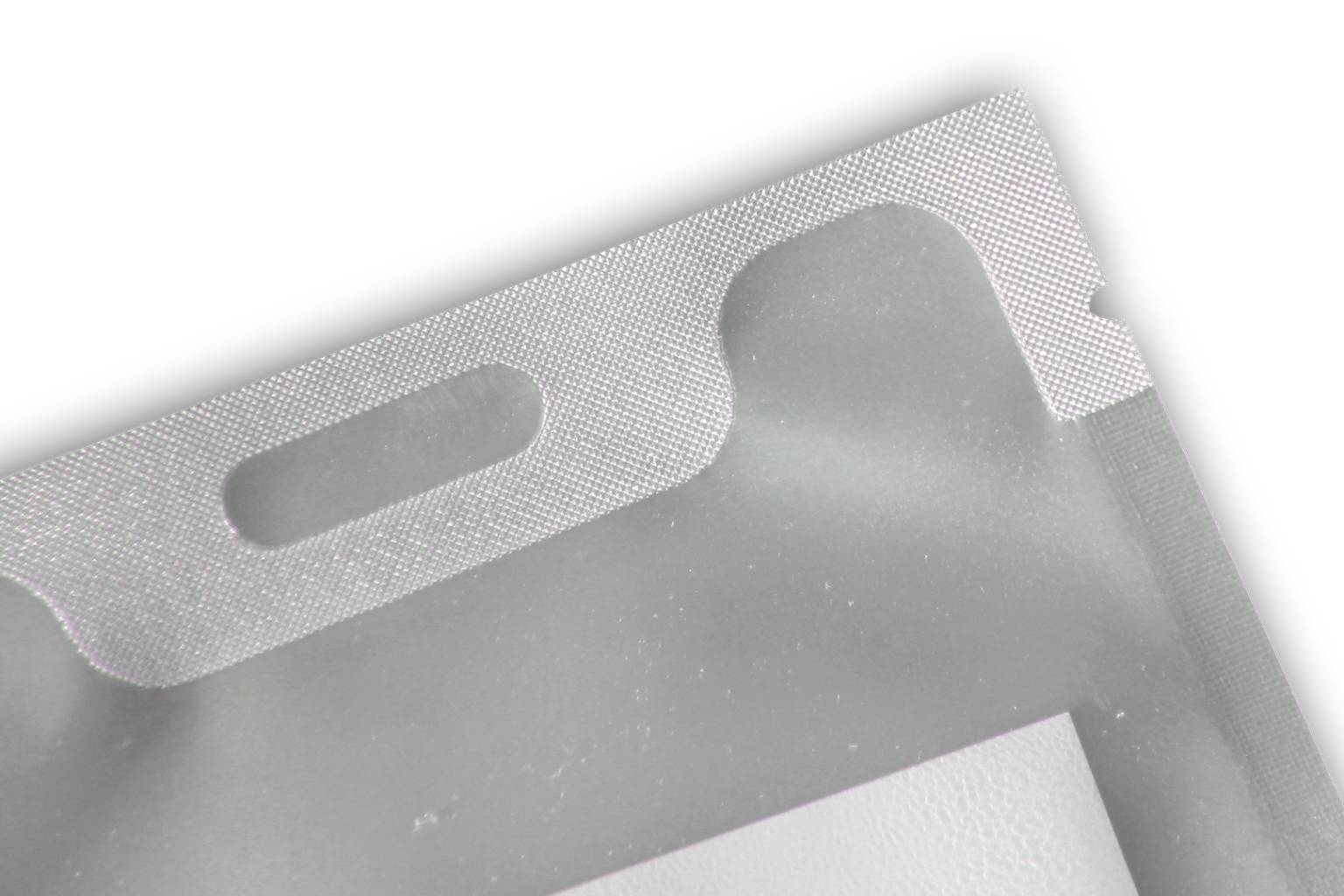

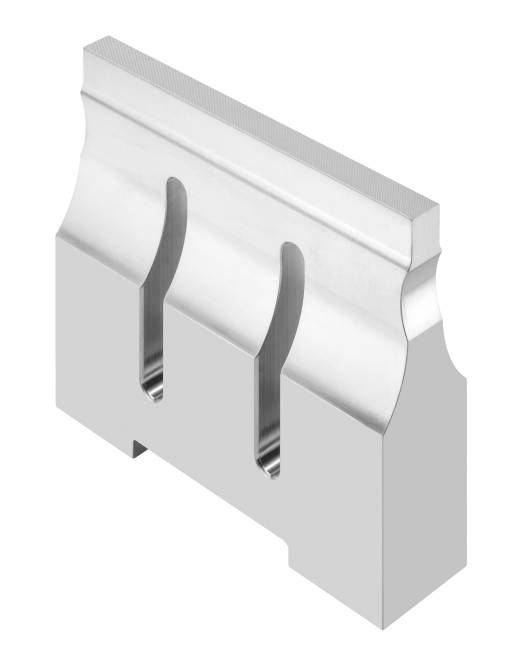

Our tools – well-chosen materials, suitable coatings, low wear and tear

Our tools are custom-developed and calculated and simulated using FEM analysis. They are made from select materials and are therefore also suitable for cleanrooms. Their high quality guarantees a long service life. Thanks to our quick-change system, tools can be replaced within just a few minutes, reducing downtimes to a minimum.

Automation & integration

Welding tools and RINCO generators installed in automation systems are used in applications such as sealing bags. The modularity of this application is also ideal for integrating standard products such as actuators and generators into automation lines or special purpose machines. We can even supply special OEM products like the AGM Pro generator, which can be controlled entirely via a system's own PLC. Multiracks support the operation of multiple generator modules.

Save energy

0timeslower energy consumption compared with the heat sealing process.

Customized

0%customisation of your sealed seam contour. There are virtually no limits when it comes to achieving the shape that you want.

Commitment

0minutesof your time will be wasted. We are a proactive partner.

Ultrasonic technology

Welding, punching and sealing can all be carried out on thermoplastics and copolymers in the form of moulds or flexible shapes. In the packaging industry, these include tubes, bottles, bags, blister packs, cardboard packaging, trays, films, double packaging and much more.

Downloads

Download our application brochure here.

Economical, energy-saving & efficient technology

The right device for every application. We provide you with tailored technology. Contact us and we will be happy to advise you.

I am here for you

Not sure whether ultrasonic technology is right for your application? Then get in touch with me!