High-tech

The highest levels of quality for welding results, wellchosen materials for tools and absolute process control thanks to recording software for validation purposes and quality assurance. RINCO offers you everything you need for a production process at the highest level. Our expert project management is based on our certifications in accordance with ISO 9001, ISO 13485 and ISO 14001.

Maximum precision for the most demanding requirements

Benefits of ultrasonics in the high-tech industry

Optimization of the process

High process speeds and short process cycles can be achieved with ultrasonics.

High flexibility

Thanks to the modular construction of our components, a manual workstation can be developed into an automation line or integrated into a special purpose machine at any time.

Economical, energy-saving and efficient

Ultrasonics not only saves you time but also uses less energy and fewer materials.

Consistent, accurate and reproducible welding results

Made possible by a database of welding parameter sets, an audit trail and very high product quality.

Audit trail function

For complete traceability and quality assurance.

Very short maintenance times

Service work can be completed in next to no time on our low-maintenance machines.

Our tools – well-chosen materials, suitable coatings, low wear and tear

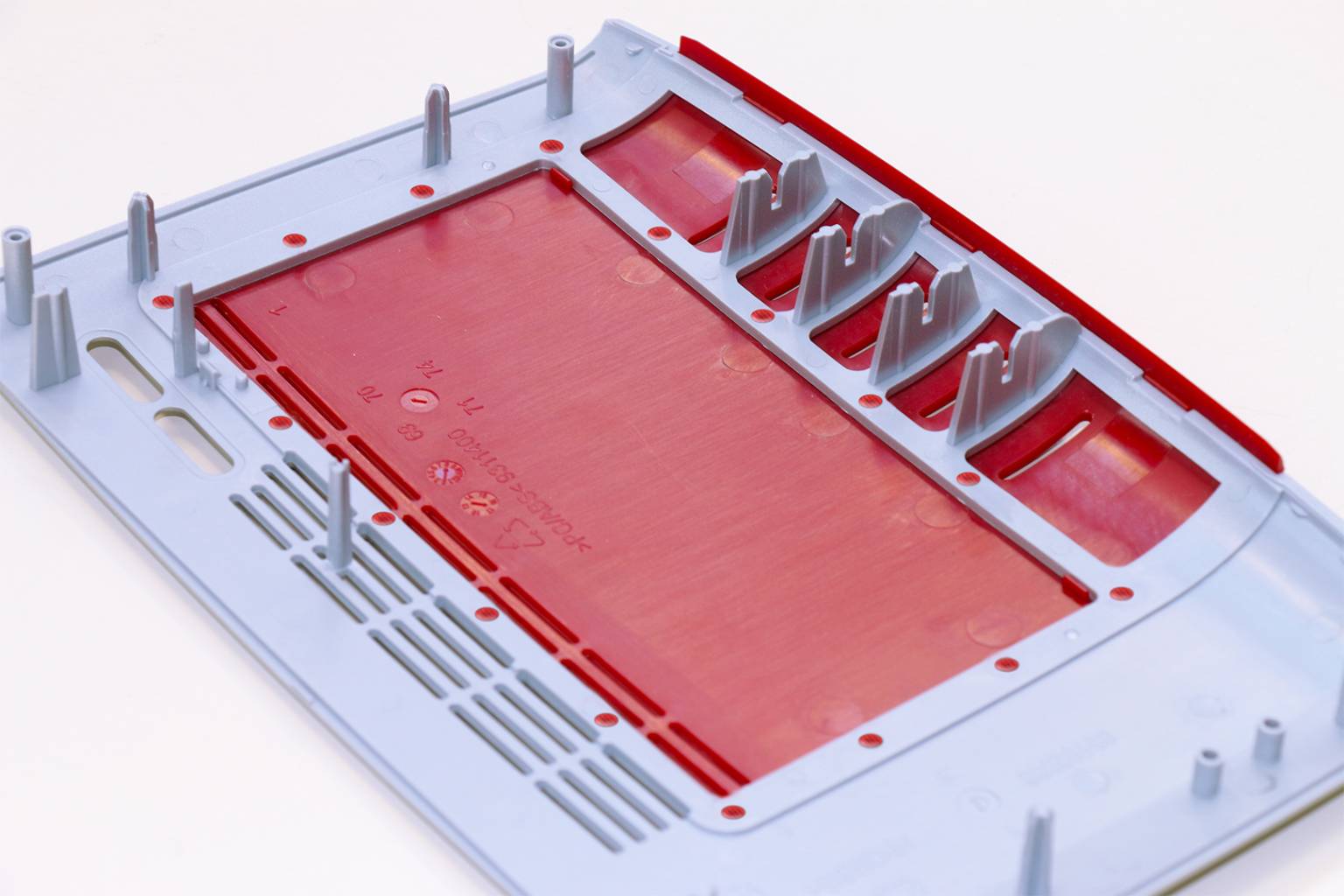

Our tools are custom-developed and calculated and simulated using FEM analysis. They are made from select materials and are therefore also suitable for cleanrooms. Their high quality guarantees a long service life. Thanks to our quick-change system, tools can be replaced within just a few minutes, reducing downtimes to a minimum.

Automation & integration

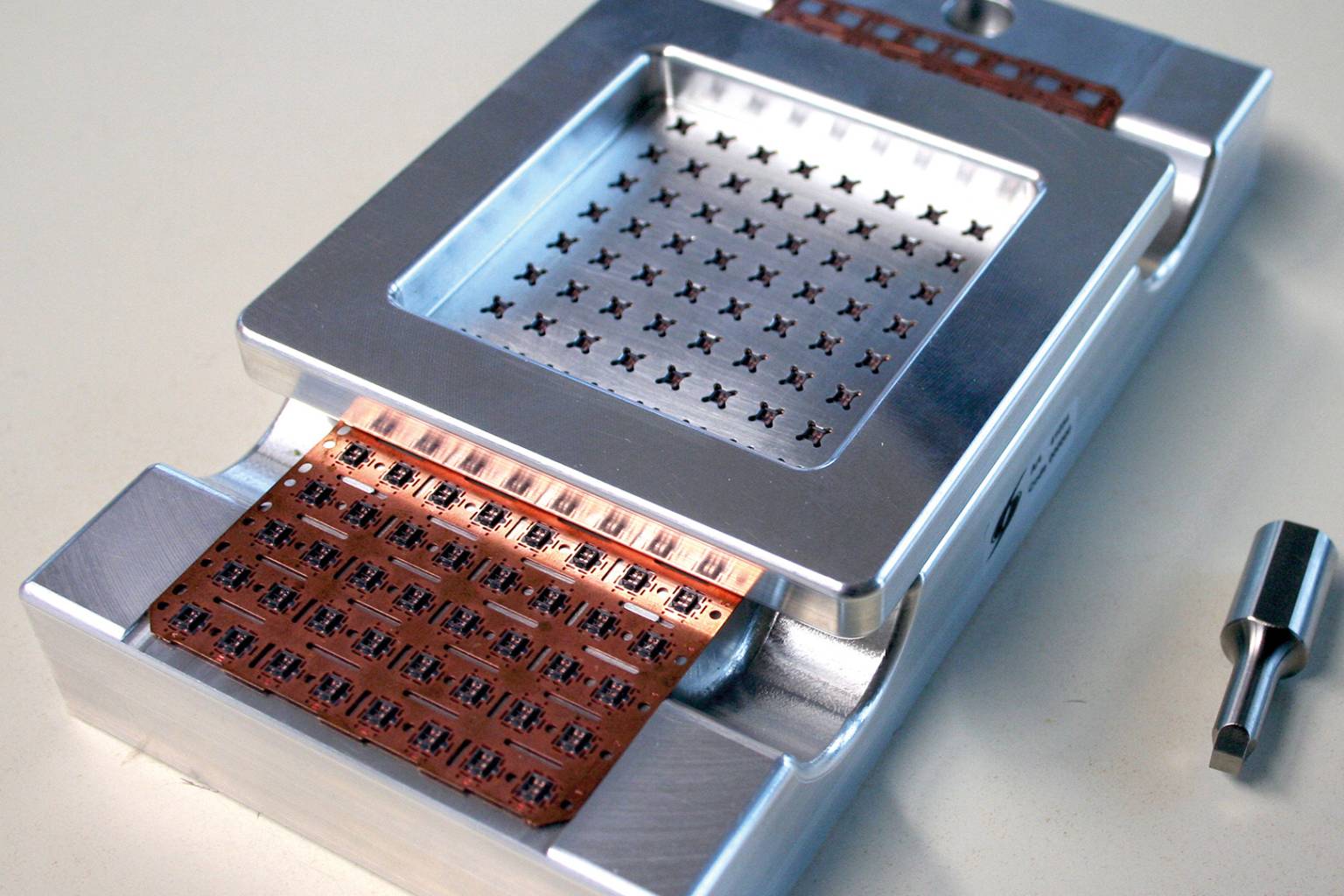

Robot-controlled welding tools and RINCO generators are used in the production of RFID inlays or NFC cards, for example, where the wire or chip is embedded in the plastic using ultrasonics. The modularity of this application is also ideal for integrating standard products such as actuators and generators into automation lines or special purpose machines. We can even supply special OEM products like the AGM Pro generator, which can be controlled entirely via a system's own PLC. Multiracks support the operation of multiple generator modules.

Ultrasonic technology

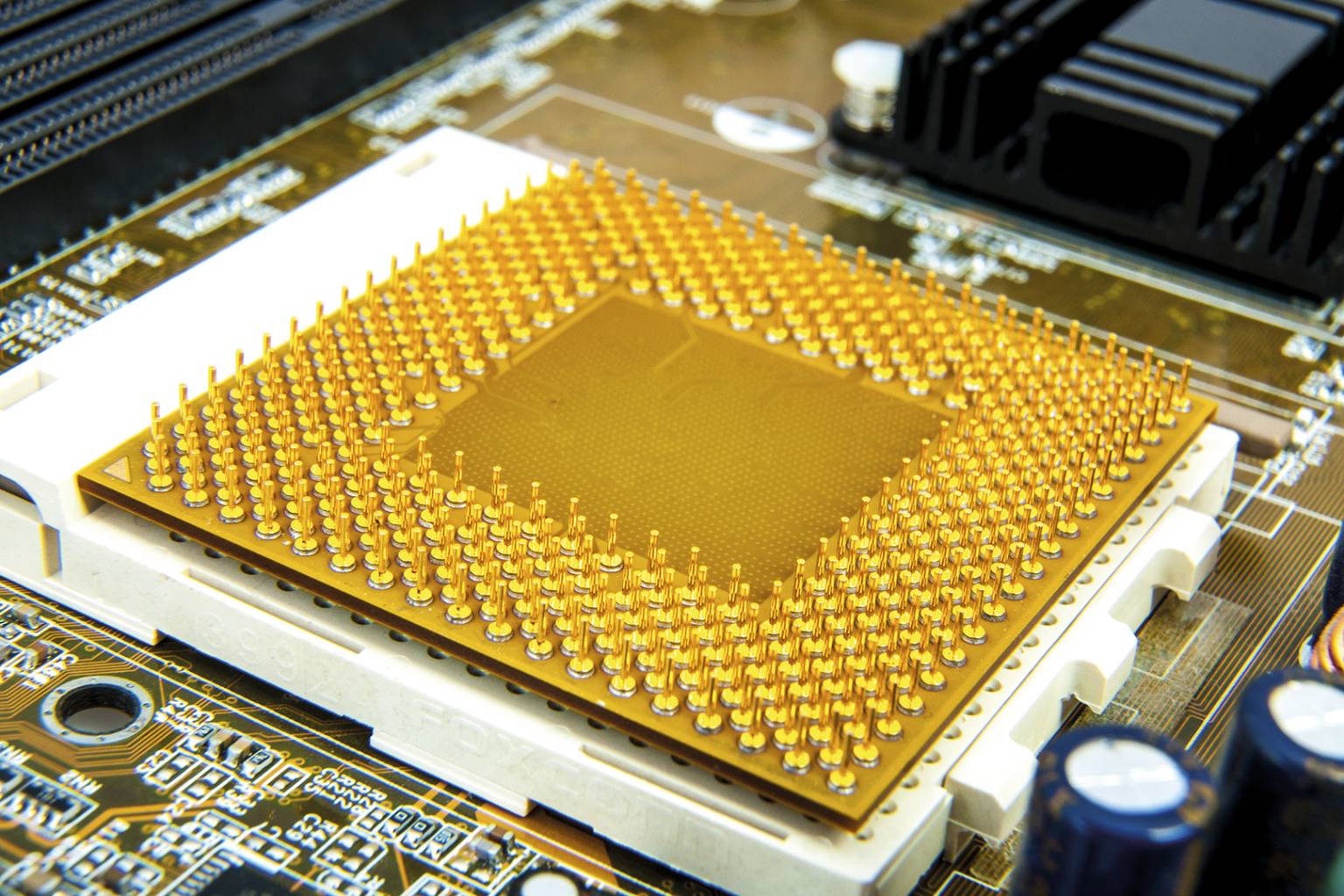

Welding, riveting, punching, die-sinking, bending and sealing can all be carried out on thermoplastics and copolymers in the form of moulds or flexible shapes. A particularly suitable operation here is inserting, which allows metals and plastic components to be joined without pre-heating the metal components or damaging the application. Cutting, punching, sealing and welding can also be carried out on technical textiles and non-woven materials.

Downloads

Download our application brochure here.

Economical, energy-saving & efficient technology

The right device for every application. We provide you with tailored technology. Contact us and we will be happy to advise you.

I am here for you

Not sure whether ultrasonic technology is right for your application? Then get in touch with me!