Ultrasonic technology

RINCO ULTRASONICS is one of the world's leading companies in the fields of ultrasonic welding and ultrasonic cutting of plastics, textiles and food.

Ultrasonic technology makes it possible to achieve virtually perfect welding and cutting results. The precision of ultrasonic welding and cutting is highly valued across a range of different sectors. The use of ultrasound enables clean, economical and sustainable processes that promote cost-effectiveness without impairing the quality of the product. RINCO ULTRASONICS has over 160 employees and representatives in more than 40 countries, all of whom understand the market and the requirements that high-quality plastic products need to fulfil.

We are celebrating a special event this year: RINCO ULTRASONICS is turning 50.

This is a milestone that fills us with both pride and humility. We feel proud of our employees, whose dedication day in and day out has made RINCO ULTRASONICS one of the leading companies in ultrasonic technology. We feel humble because successfully mastering technological, economic, and social challenges over five decades is not something that can be taken for granted.

All the more reason to celebrate this anniversary together. Join us throughout our anniversary year and discover retrospectives, insights, and special moments – and celebrate with us on LinkedIn and Facebook.

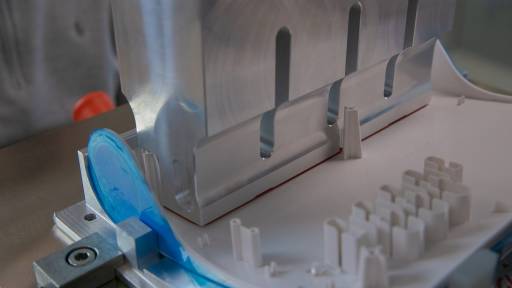

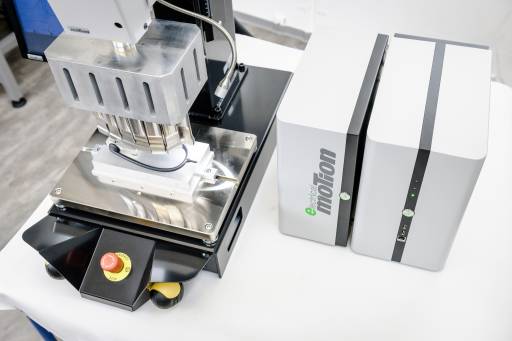

The highest levels of quality and precision: with versatile ultrasonic welding technology to create a quality product. The automotive, food processing, medical technology and textile industries, to name just a few examples, all rely on the perfection delivered by ultrasonic welding and cutting. We will show you how and where our devices are used.

Whether it is a standardised ultrasonic welding machine or an OEM solution developed specifically for you, each of our products embodies decades of experience and expertise and delivers outstanding flexibility. Most of our ultrasonic products have a modular structure, which allows the machines to be used in a flexible manner. For example, the machine components of a bench-top workstation can be integrated into automation lines or special machines.

Ultrasonic technology is versatile. Not only are welding and cutting possible, but also punching, sealing, riveting, beading and inserting. We explain exactly how the individual processes work on our knowledge pages.

Are you looking for a new job? We are looking for you! Check out our job vacancies and find out what you can expect from us.

Go to the job vacancies

It is important to us that our daily work has only a minimal impact on the environment. Our ISO 14001 certification confirms that this is the case. Find out what we are doing in this area.

Find out more

Here you will find all the latest news, trade fair appearances, press reports and everything else that is happening at RINCO...

Go to the newsOur customers, suppliers and employees know what sets us apart. All the more reason why we are delighted that our striving for perfection is also officially recognised.